China’s 1st 5-star Hotel VRF System Braze-free Retrofitting Project by NEXCON

2020-12-14 14:18:00

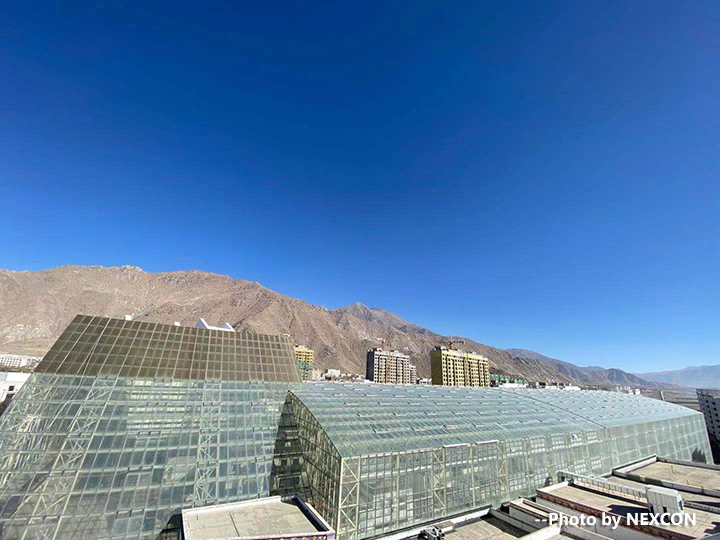

Intercontinental® Lhasa Paradise Hotel is one of the few high-altitude hotels in the world. The natural landscape around the Lhasa River was fully considered in the initial planning stage. According to the local topography and hydrological conditions, “sky high, the earth far”, “floating white clouds, cascading snow mountain” is the the design concept. With Jiangsu Avenue as the central axis, is divided into three groups of "white triangle buildings" symmetrically, forming a patchwork of snow mountain shapes, standing beside the blue lake, mirrors, blue sky, white clouds, reflections, reflecting each other.

InterContinental® Lhasa Paradise Hotel (Image from the Internet)

In order not

to affect the normal daily business of the hotel to the greatest extent and the

local CPPCC meeting in the first half of 2021 to be held as scheduled, the

hotel decided to install VRF system with braze-free connection technology. With a total investment

of 1.8 billion RMB (275 million USD), the InterContinental® Lhasa Paradise

Hotel covers an area of 350 mus (233,450 square meters), with a total

construction area of 212,000 square meters, and a total of 2,000 rooms.

Retrofitting construction area of this project is about 41,000 square meters.

It is the largest five-star hotel in Tibet. The

project contains 66 VRF outdoor units and 523 indoor units, with a total

cooling capacity of more than 3000kw.

Rooftop of Hotel VRF units

Hall&Interior of Hotel

In the early stage of the project, in order to do its best to meet the needs of the project, NEXCON tentatively prepared all materials in production to arrange the required goods for the project. It only took ten days to get the goods ready and shipped by air to Lhasa, then to the project site.

NEXCON dispatching goods NEXCON goods arrived at project warehouse

Training at the hotel

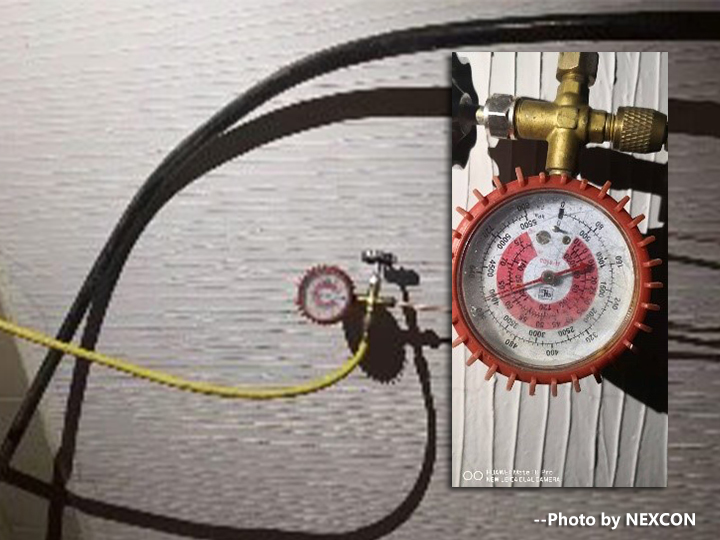

The installation of the sample floor was completed on December 4th as of time of report. Pressure-holding tests are without any defect. All floors will be installed in the following months.

Sample floor pressure-holding test